Why Electron Beam Welding

Redefined Efficiency

At Artech, we are committed to providing the most advanced and versatile welding technologies to meet the diverse needs of industries worldwide. One such technology that has gained significant traction in precision-driven sectors is Electron Beam Welding (EBW).

Artech’s decision to integrate EBW into our portfolio stems from its exceptional benefits, making it the go-to solution for industries that demand high-precision, efficiency and versatility.

The Advantages of Electron Beam Welding

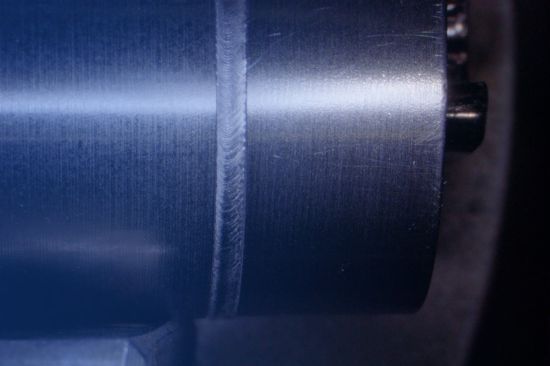

Artech Welders’ high depth-to-width ratio eliminates the need for multiple-pass welds, reducing production time and effort. The deep penetration minimizes shrinkage and distortion, enabling precise welding even near heat-sensitive components.

Precision and Accuracy

EBW uses CNC technology for precise welding up to 0.5 mm, making it ideal for narrow and deep welds.

Efficiency and Cost-Effectiveness

Converting up to 85% of electricity into the weld EBW is Power efficient. It doesn’t need filler metals or flux, thus reducing material costs

Minimal Distortion and Enhanced Strength

EBW uses low heat, reducing the risk of distortion and helping the welded parts stay strong and intact.

Ideal for Delicate Materials

Ideal welding process for industries dealing with delicate or heat-sensitive materials, like thin components or sensitive alloys.

Versatility in Materials

Can used for both similar and dissimilar metals such as steel, titanium, and exotic alloys, providing high-quality welding results.

Support for Additive Manufacturing

It is a perfect solution for joining 3D printed parts with high precision and minimal heat distortion, making it ideal for advanced manufacturing.

Innovating Welding Excellence

Integrating Electron Beam Welding (EBW) into our portfolio marks a significant step forward for Artech in innovation and technology. With its precision, efficiency and versatility, This has opened new opportunities across industries, from aerospace to medical devices.

Our new technology enables customers to meet even the most challenging welding requirements, paving the way for next-generation products with exceptional reliability and performance.