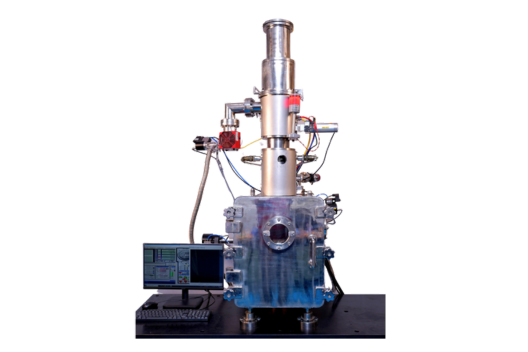

Electron Beam Welding

EBW System by Artech

Key Features

High Precision & Deep Penetration

It delivers highly accurate welds with deep penetration, making it perfect for joining thick and complex metal workpieces.

Versatility in Materials

Artech’s EBW can weld various metals, including aluminum, stainless steel and specialized alloys like Inconel and Hastelloy, even when joining dissimilar materials.

Vacuum Environment

This new systems operate in a vacuum, ensuring clean, flawless welds and preventing defects like cracks or blowholes.

Energy-Efficient

EBW systems convert up to 85% of electrical input into usable power, offering an energy-efficient solution for high-precision welding needs.

Key Features

High Precision & Deep Penetration

It delivers highly accurate welds with deep penetration, making it perfect for joining thick and complex metal workpieces.

Vacuum Environment

This new systems operate in a vacuum, ensuring clean, flawless welds and preventing defects like cracks or blowholes.

Versatility in Materials

Artech's EBW can weld various metals, including aluminum, stainless steel and specialized alloys like Inconel and Hastelloy, even when joining dissimilar materials.

Energy-Efficient

EBW systems convert up to 85% of electrical input into usable power, offering an energy-efficient solution for high-precision welding needs.

Why Choose Us

High weld speed

High weld penetration

Narrow weld bead

Low heat input and distortion

Low heat affected zone

Reactive materials can be welded

Refractory materials can be welded

Thick to thin materials can be welded

Technical Specifications

| Parameter | Specification |

| Electron Gun Capacity | 60 kV, 4 kW |

| Work Chamber Size | 460 mm x 480 mm x 560 mm |

| Electron Gun Vacuum | 1 x 10-6 mbar |

| Chamber Vacuum | 5 x 10-6 mbar |

| Manipulator | 150 x 150 mm XY coordination table, demountable rotary table with vertical and horizontal axes |

Material

- Aluminium

- Bronze

- Cobalt alloys

- Copper

- Hastalloy

- Inconel

- Super alloys

- Magnesium

- Carbon steel

- Nickel

- Stainless steel

- Titanium

- Zinc

- Zirconium

- Niobium

- Molybdenum

- Dissimilar metals

- All conventional weldable materials

Frequently Asked Questions

What is electron beam welding used for?

EB welding well-suited to joining components that require high accuracy, deep penetration and little contamination. It’s mostly used in aerospace, automotive and high-tech sectors, where these considerations are crucial.

How much does electron beam welding cost?

EB Welding can also be a more costly process than traditional welding methods due to the complex equipment and vacuum setup involved. The advantages in precision and material compatibility make it economical for high-end, high-strength applications.

Does EBW require a vacuum?

Yes, a vacuum is critical for EB Welding because it eliminates air particles in the beam path that would scatter the electrons, leading to loss of weld quality and control at the weld centerline. It also keeps the weld pool from being contaminated.

How fast is electron beam welding?

The fast speed, about 200 mm per minute, makes EB welding a more effective process since it does not require time-consuming activities such as polishing compared to other methods like TIG welding, so EBW is preferred for high production jobs.

Is electron beam welding the same as laser welding?

No, EB welding uses high-speed-moving electrons, while laser welding uses focused light energy. EBW is more efficient than lasers for such application since it has deeper penetration and less heat loss.